Tailor‑made solutions

Dana TM4 electric motors, inverters, and control systems are optimized for a wide range of electric and hybrid vehicle applications:

- Light Vehicles

- Commercial Vehicles

- Off‑Highway

Dana TM4 electric motors, inverters, and control systems are optimized for a wide range of electric and hybrid vehicle applications:

Being a system supplier means more than providing motors and controllers. We focus on supplying the right motor and controller to optimize efficiency, performance, and cost for your application.

The Dana TM4 Sales & Application Engineering team partners with OEMs from concept through production, using proprietary simulation tools to select and harmonize the right powertrain components.

Proven technologies enabling simple integration, high efficiency, and lower maintenance costs — available at mass‑production scale.

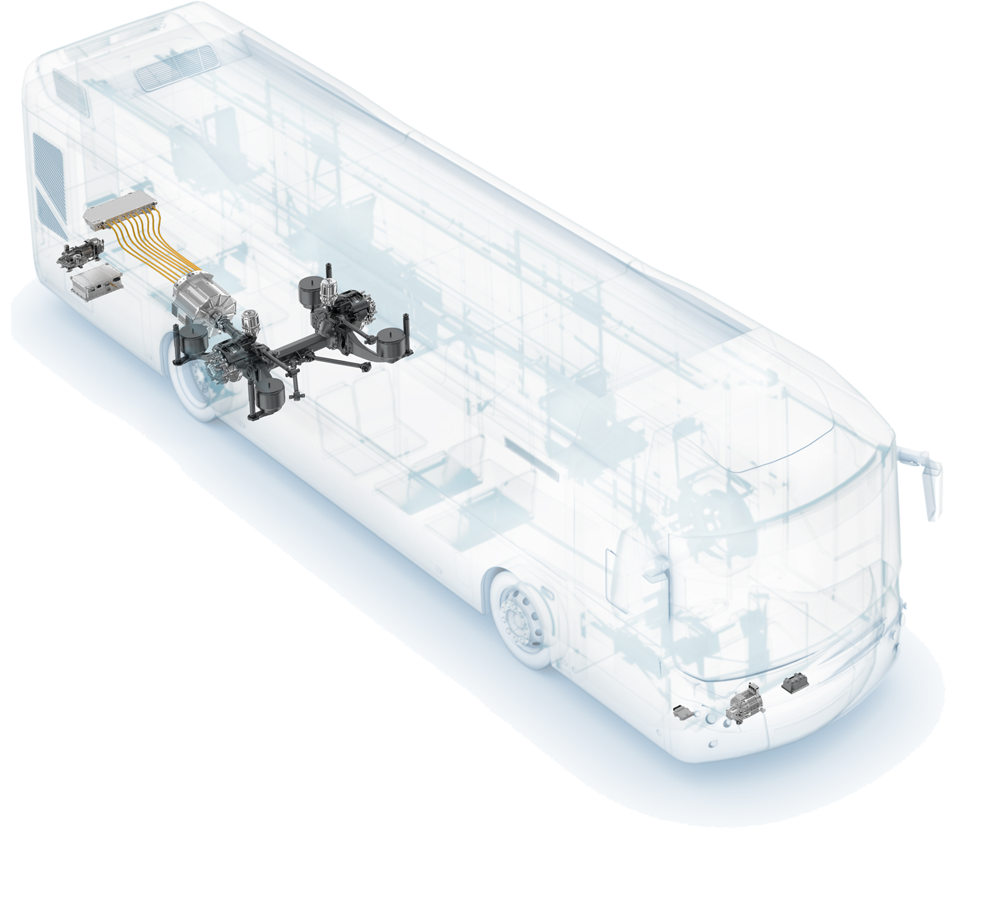

COMMERCIAL VEHICLES

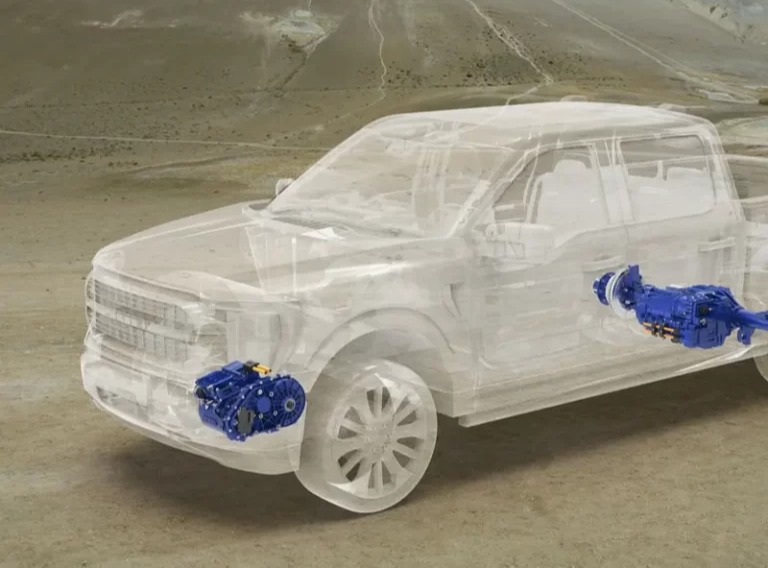

LIGHT VEHICLES

MATERIAL HANDLING

CONSTRUCTION VEHICLES

SPECIALTY ELECTRIC

MINING VEHICLES

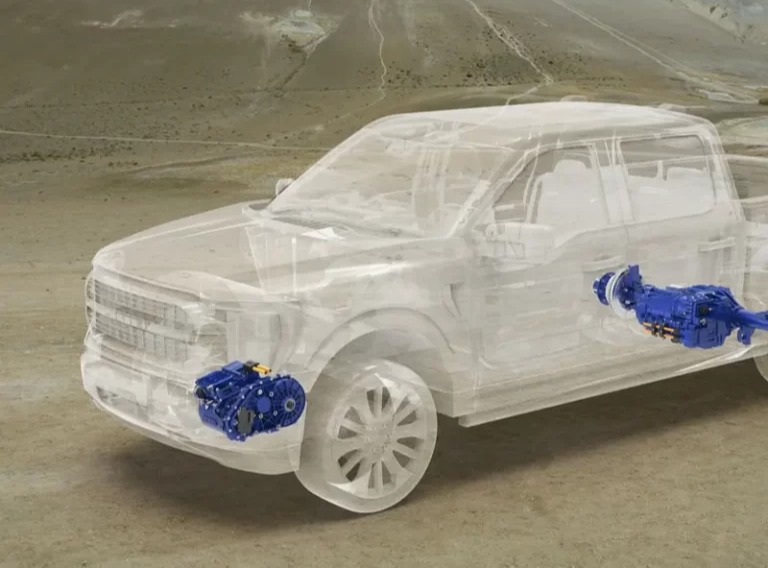

Dana TM4 can supply both traction and auxiliary solutions optimized for medium-and heavy-duty electric and hybrid vehicles such as:

Depending on the vehicle type, we recommend various configurations and solutions:

| VEHICLE TYPE | GCW | DANA SOLUTION |

|---|---|---|

City Buses, School Bus and Intercity

City Buses, School Bus and Intercity

|

10-26T |

Direct-drive

|

Class 4

Class 4

|

<8T |

e-Axle

|

Class 5

Class 5

|

8-10T |

e-Axle

|

Class 6

Class 6

|

10-12T |

e-Axle

|

Class 7

Class 7

|

12-16T |

Direct-drive

|

Class 8

Class 8

|

18 to < 28T |

Direct-drive

|

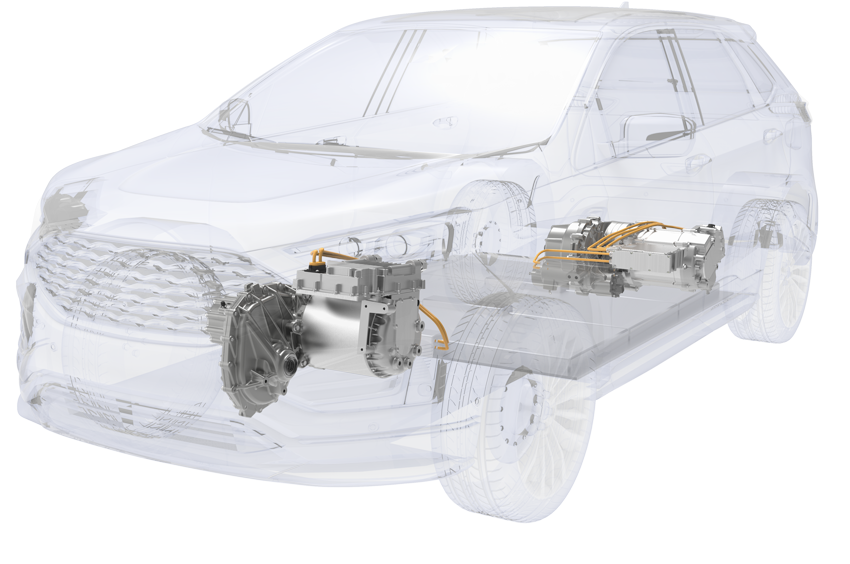

Dana TM4 e-motors and inverters for light vehicles are scalable solutions optimized for:

Our systems are a cost-effective solution to vehicle electrification, designed and optimized for components to operate at the highest efficiency while getting the best performance out of the package.

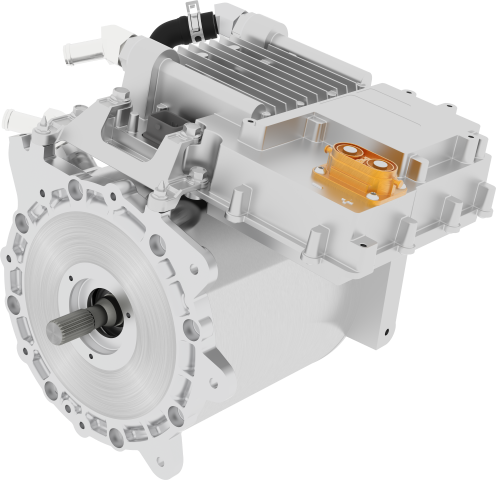

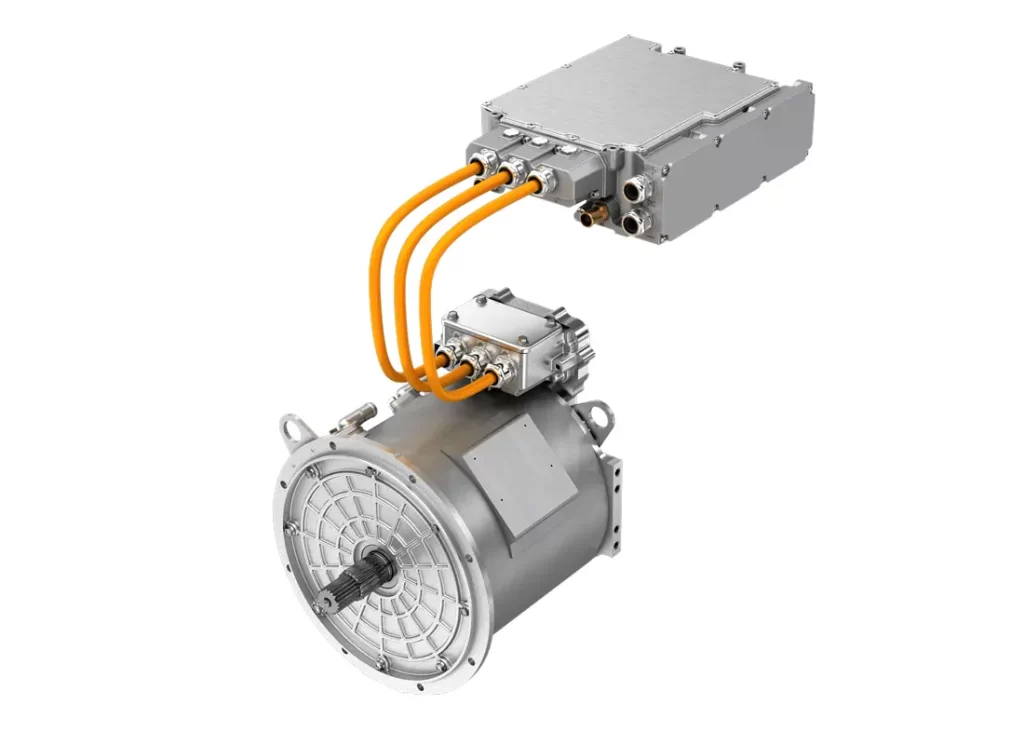

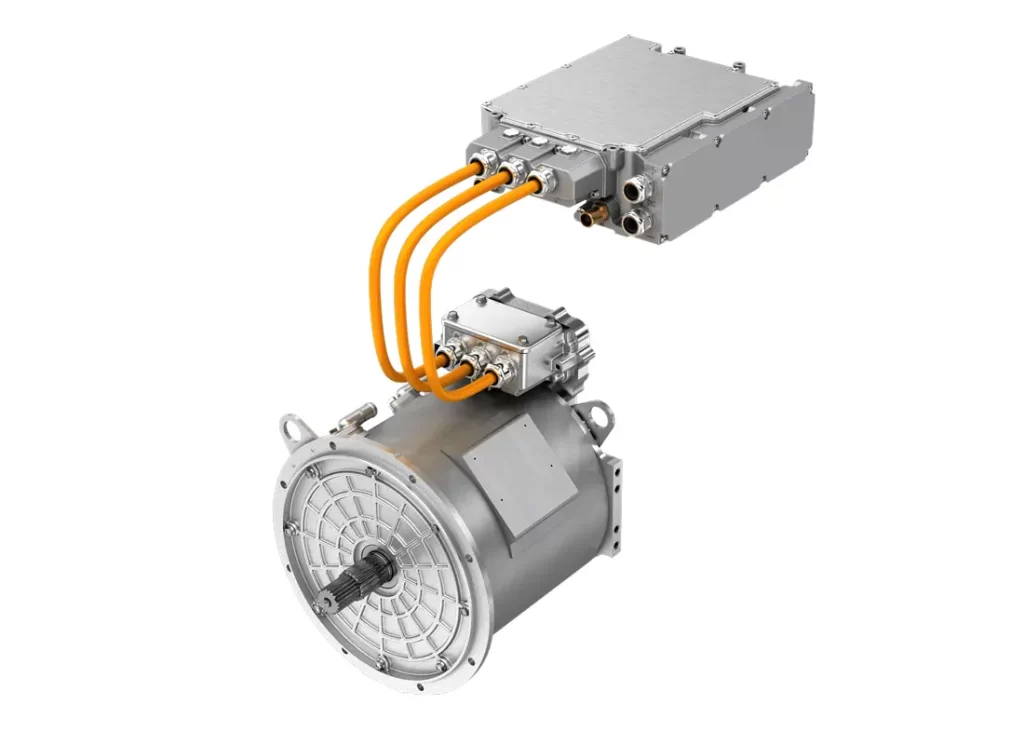

The TM4 MOTIVE motor and inverter are an integrated system featuring high-RPM permanent magnet electric motors, power-dense electronic inverters, and advanced controls that enable electric vehicles to meet the highest standards for efficiency, reliability, and performance.

These systems are a cost-effective solution to vehicle electrification, designed and optimized for components to operate at the highest efficiency while getting the best performance out of the package.

Electric auto-rickshaws are becoming increasingly popular in Asian markets. They not only offer environmental benefits but also social advantages, providing a low-cost solution for people finding it difficult to access their own transport.

Generally manufactured in India and China, our Asian presence allow us to supply this growing market.

Electric motor technology has come a long way since the first custom-made golf car was manufactured in 1932. Although there have been petrol variants since then, electric power has long been the preferred choice.

We work with some of the biggest names in golf car manufacturing, delivering reliability at high-volume.

Our IPM motor with its patented advanced technology will achieve greater efficiency through increased battery life, meaning you can go further on a single charge.

Low-voltage IPM motors ranging from 24 – 96 V and 10–95 Nm.

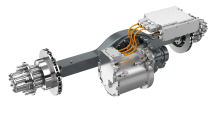

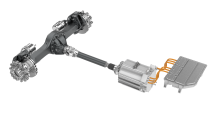

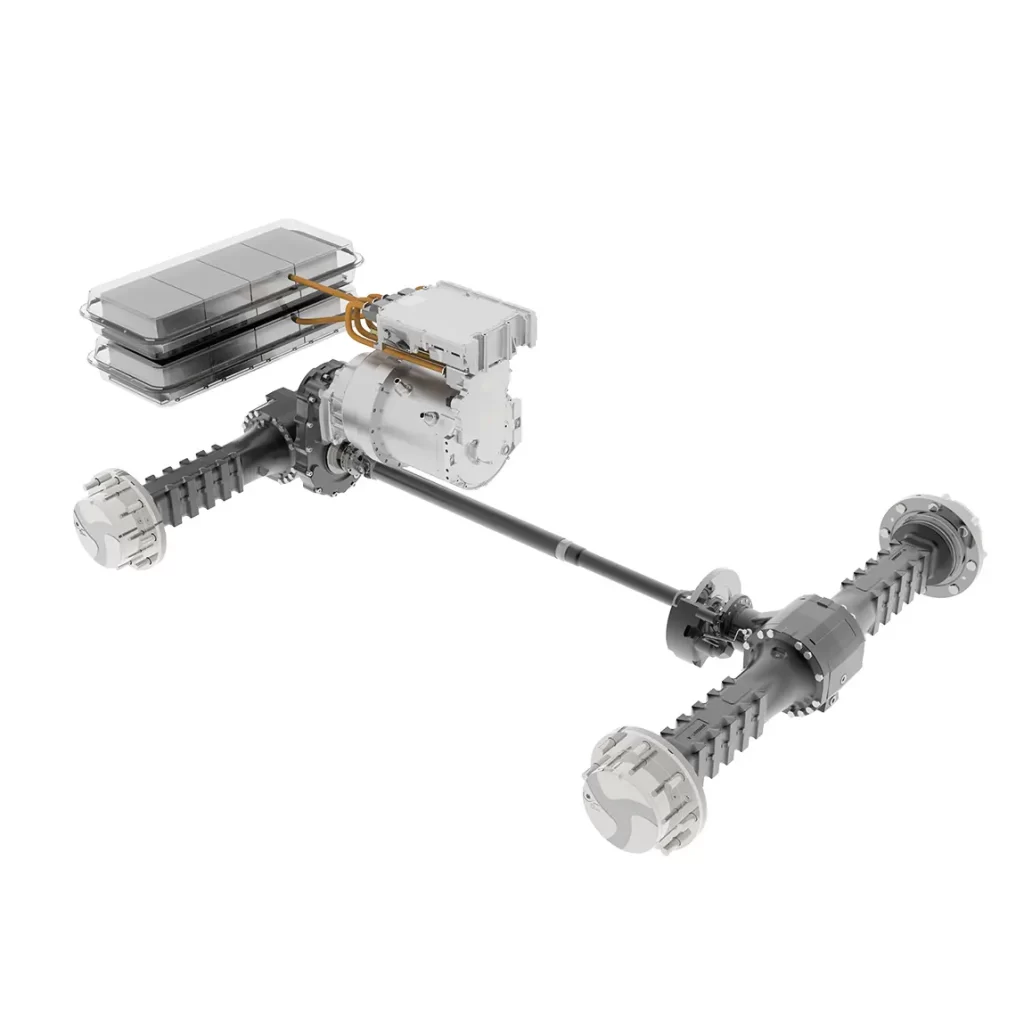

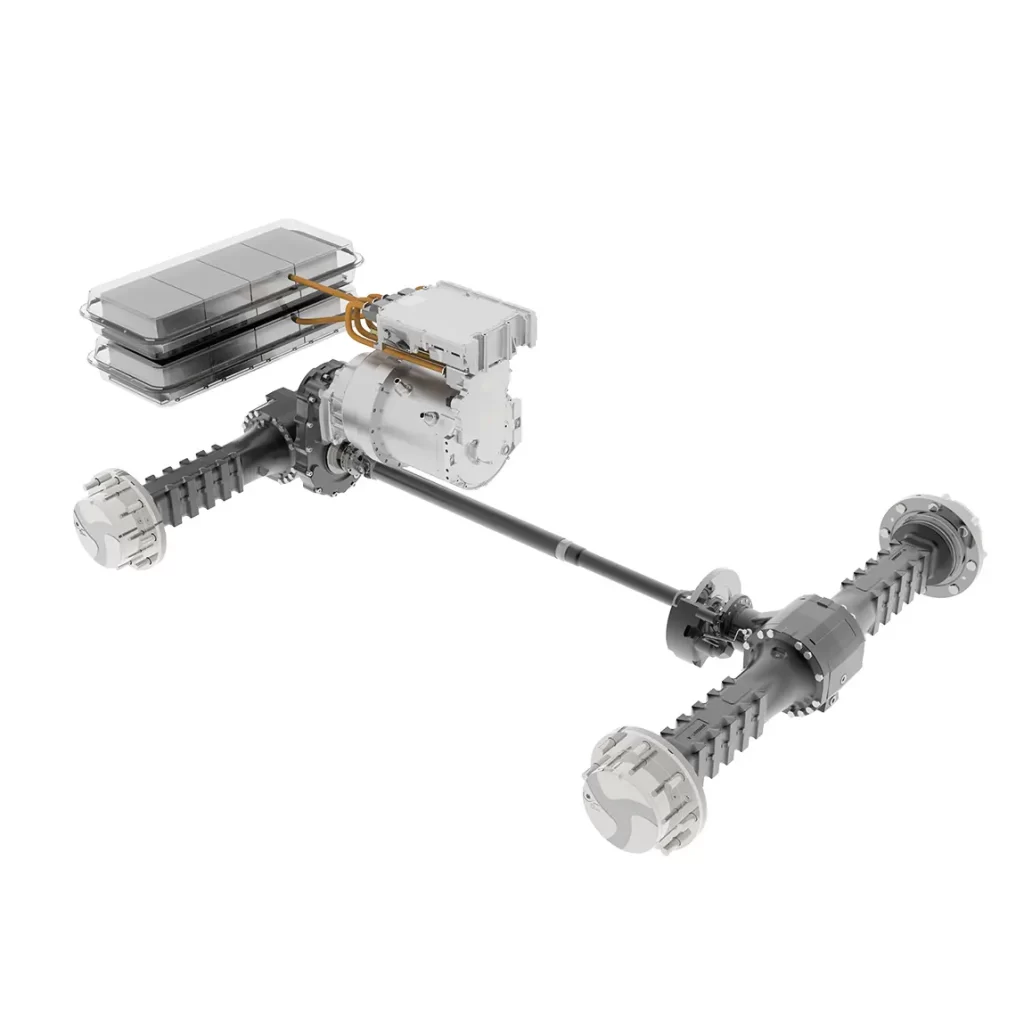

Dana TM4 products are designed to fit seamlessly with Dana e-Axles and gearboxes.

Integrated high-voltage system featuring high-RPM permanent magnet electric motors, power-dense electronic inverters, and advanced controls.

Dana TM4 motors and inverters are scalable solutions for:

Our teams work closely with OEMs to determine whether a fully electric or hybrid solution is best — from concept and prototyping through high‑volume production.

Electric forklifts produce zero emissions and noise — perfect for indoor operations. Dana TM4 motors deliver exceptional efficiency, extending battery life and run time.

Compact, powerful, and easy to maintain.

AGVs navigate warehouses autonomously — Dana TM4’s modular motors and inverters maximize efficiency, reliability, and uptime.

We partner with OEMs to tailor solutions by load, torque, speed, and footprint.

24V–144V | 2–70 kW

350V–750V | 70–350 kW

24V–96V | 40–500A

36–144V | 250–750A

24–80V | 75–750A

Seamless integration with Dana e‑Axles

Dana TM4 voltage motor and inverters provide optimum performance for multiple construction applications including:

Our teams work closely with OEMs to understand if their application is best suited to a fully electric or hybrid solution, and support them from prototype and concept stage right through to high-volume production.

Our low-voltage motors are put through stringent quality checks to ensure greater reliability, resulting in fewer scheduled services and downtime.

Our motors, paired with a range of Dana transmissions offer a best-in-class traction solution. An electric motor can also be used to power hydraulics. With no chains, cables or rollers to adjust, operating costs are significantly reduced.

The electric excavator has been heralded as a major breakthrough in the construction industry because it can be used in environments where traditional diesel machines are not allowed to operate, providing greater flexibility and productivity.

Our low-voltage motors are compact and modular, enabling OEMs to design smaller and narrower vehicle profiles for use inside buildings and tunnelling.

Telehandlers are relative newcomers to the electrification market, with many vehicles still in the prototype and concept phase.

As part of Dana Incorporated, we can provide a complete solution where our motors work seamlessly with Dana electrified axles, pumps and torque hubs.

24V–144V | 2–70 kW

350V–750V | 70–350 kW

24V–96V | 40–500A

36–144V | 250–750A

24–80V | 75–750A

Seamless integration with Dana e‑Axles

Dana TM4 can supply low‑ to high‑voltage motors and inverters optimized for:

Our low‑voltage inverters have the best power density in the market thanks to our patented DBC MOSFET power modules.

24V–144V | 2–70 kW

36–144V | 250–750A

24–80V | 75–750A

Dana TM4 motors and inverters are scalable solutions for:

Proven technologies enabling simple integration, high efficiency, and lower maintenance costs — all at production‑scale pricing.

Some TM4 SUMO systems interface directly with differentials, gearboxes, and e‑axles, resulting in: