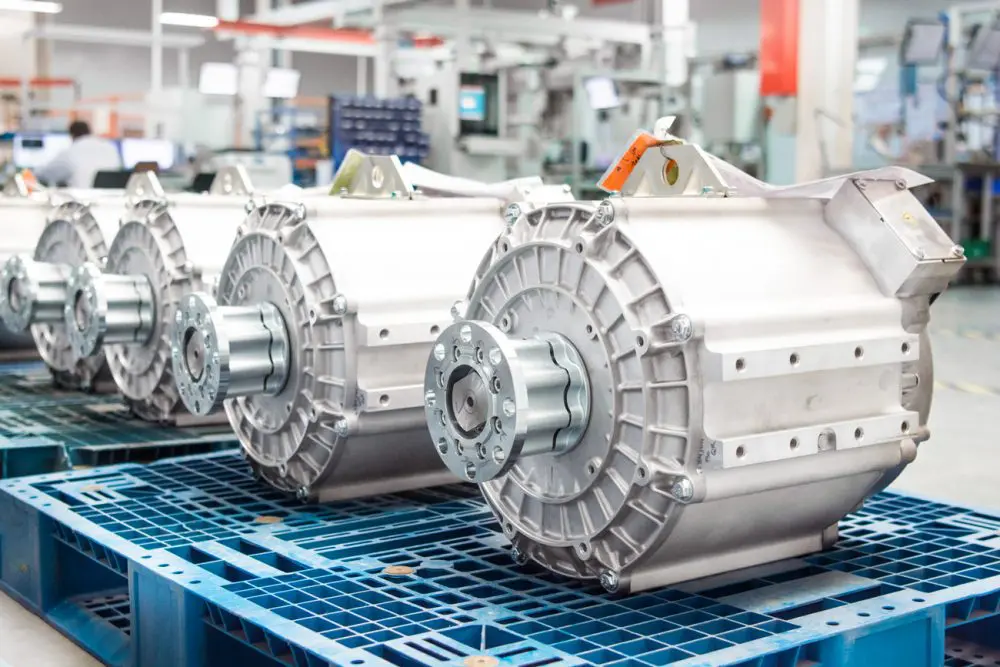

Motor and inverter systems

Built to last

Dana TM4 offers high-voltage motor and inverter systems featuring permanent magnet electric motors, power-dense electronic inverters, and advanced controls that enable electric vehicles to meet the highest standards for efficiency, reliability, and performance.

ePTO SUMO™ LD HV1200

Motor and inverter system

Peak power: 175-235 kW

Number of models: 3

Max torque: 775-1200 Nm

Interfaces directly with hydraulic pumps; heavy auxiliary applications.

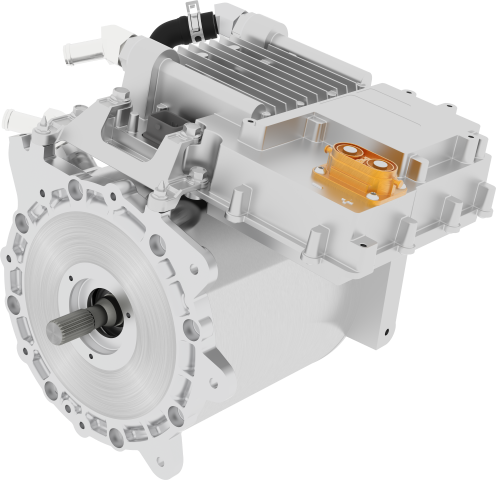

TM4 MOTIVE™

Integrated motor and inverter system

Peak power: 180 kW

Number of models: 2

Max torque: 360 Nm

Enables electric vehicles to meet the highest standards for efficiency, reliability, and performance; systems are efficient turnkey solutions optimized for passenger cars and commercial vehicles up to class 2.

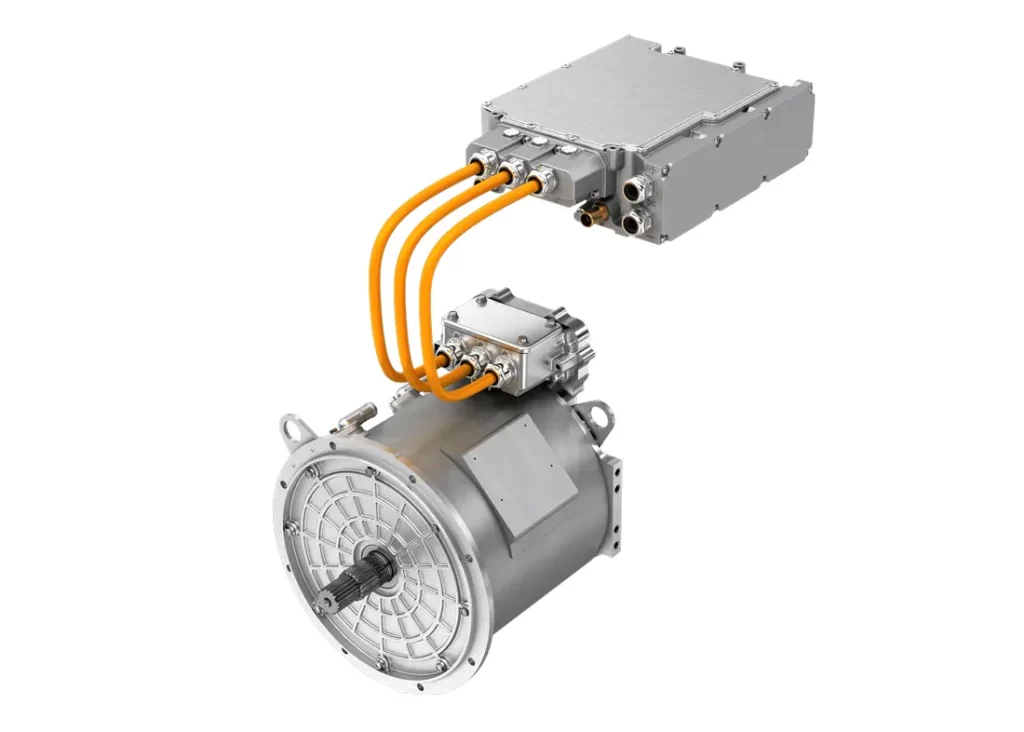

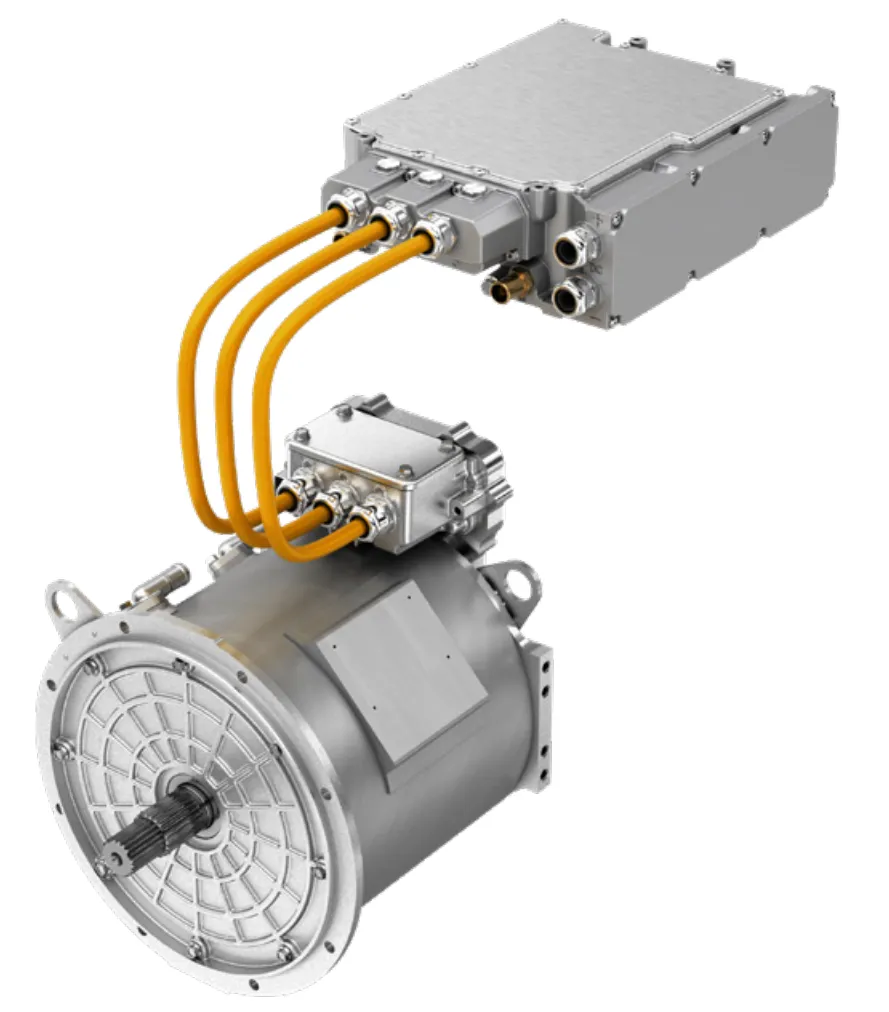

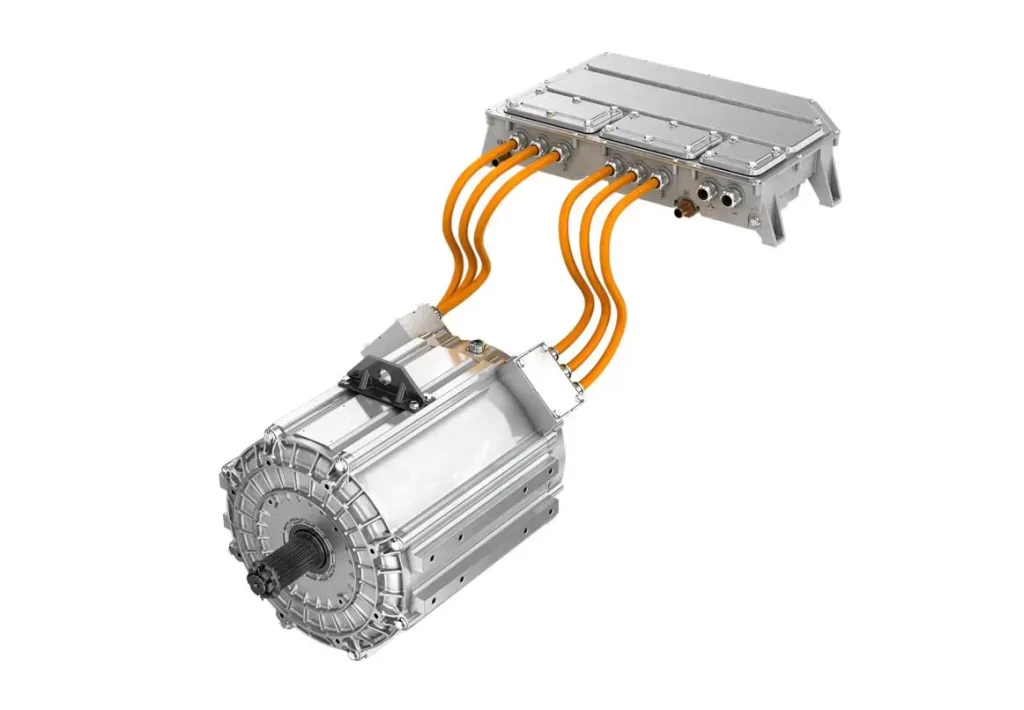

TM4 SUMO™ LD

Motor and inverter system

Peak power: 175-235 kW

Number of models: 3

Max torque: 775-1200 Nm

Integrates seamlessly with Dana’s e-Axle and gearboxes. Operating voltage 300-800 Vdc.

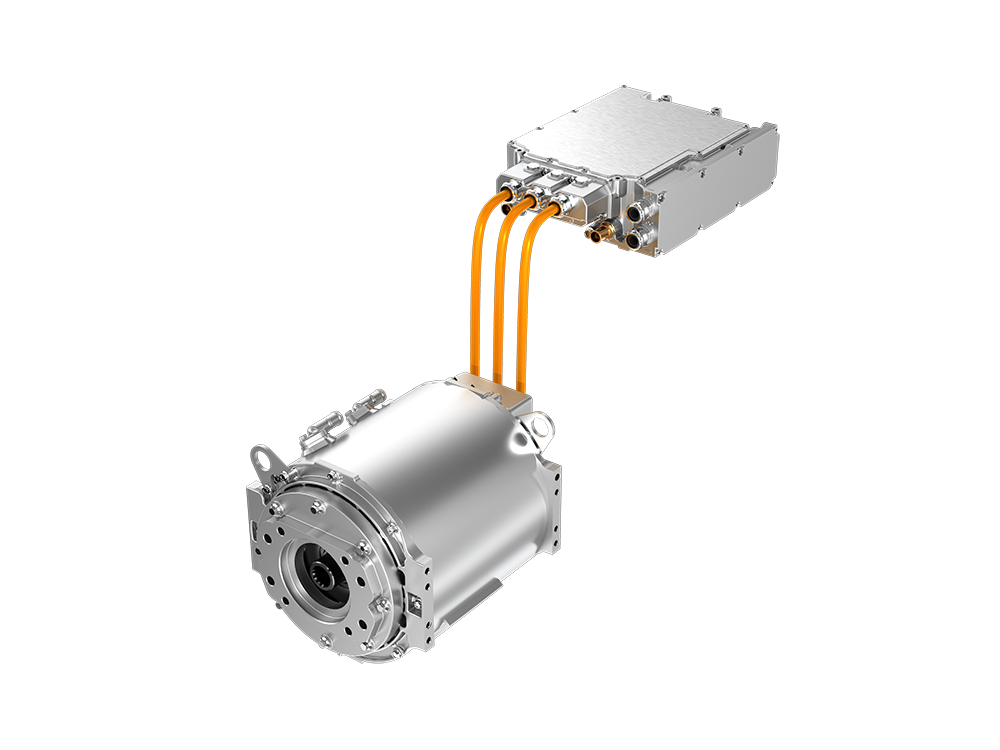

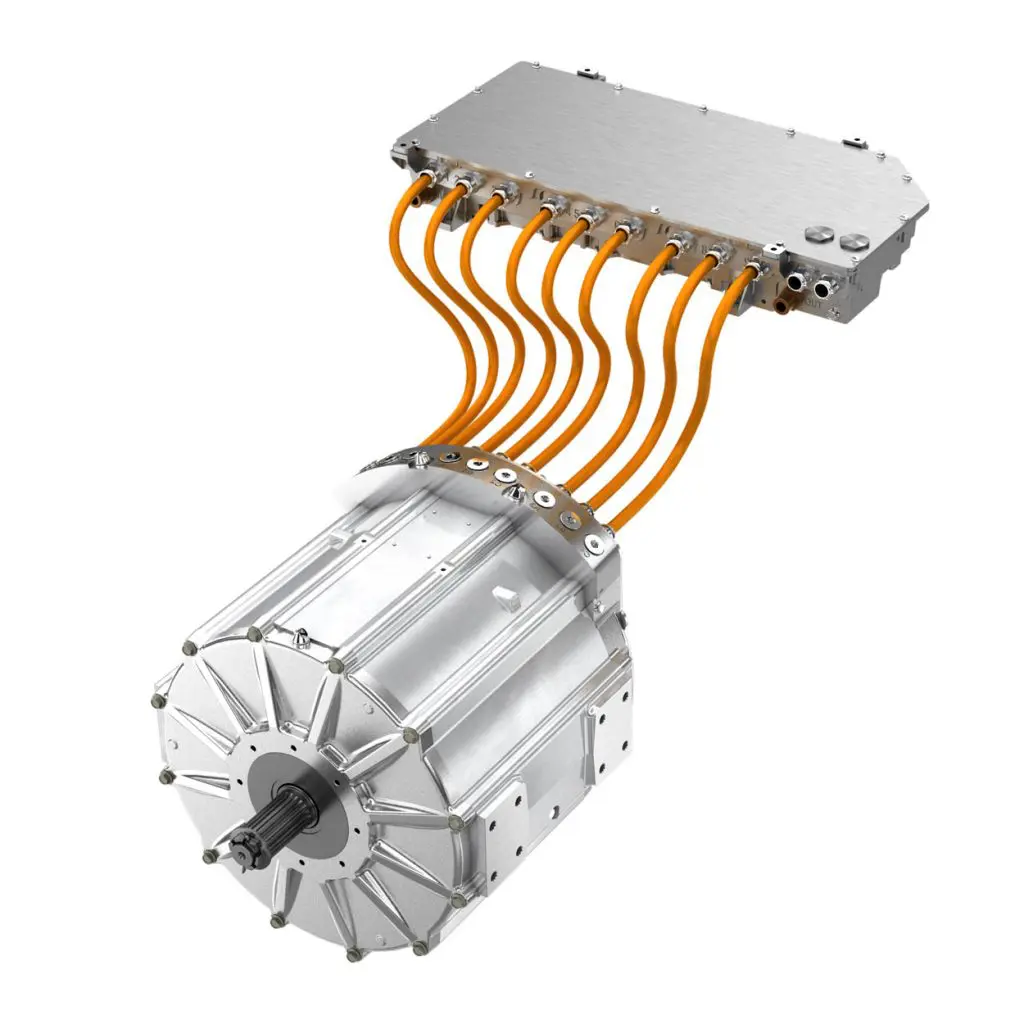

TM4 SUMO™ MD

Motor and inverter system

Peak power: 170-300 kW

Number of models: 10

Max torque: 1775-3320 Nm

Interfaces directly with standard axles (no gearbox required). It makes this series perfect for class 4 to 7 commercial vehicles, bus platforms, and off-highway applications.

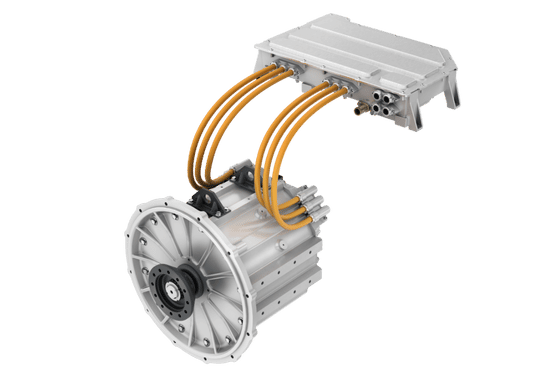

TM4 SUMO™ HD

Motor and inverter system

Peak power: 250-475 kW

Number of models: 3

Max torque: 3415-4000 Nm

Interfaces directly with standard axles (no gearbox required). Its direct drive/gearless approach makes it the perfect match for any heavy-duty commercial vehicle platforms, bus platforms and off-highway applications.

TM4 SUMO™ HP

Motor and inverter system

Peak power: 430-540 kW

Max torque: 2500 Nm

Features a new motor with compact concentric winding technology to deliver maximum torque density and leverages Dana's proven internal permanent magnet technology for optimal efficiency and cost.

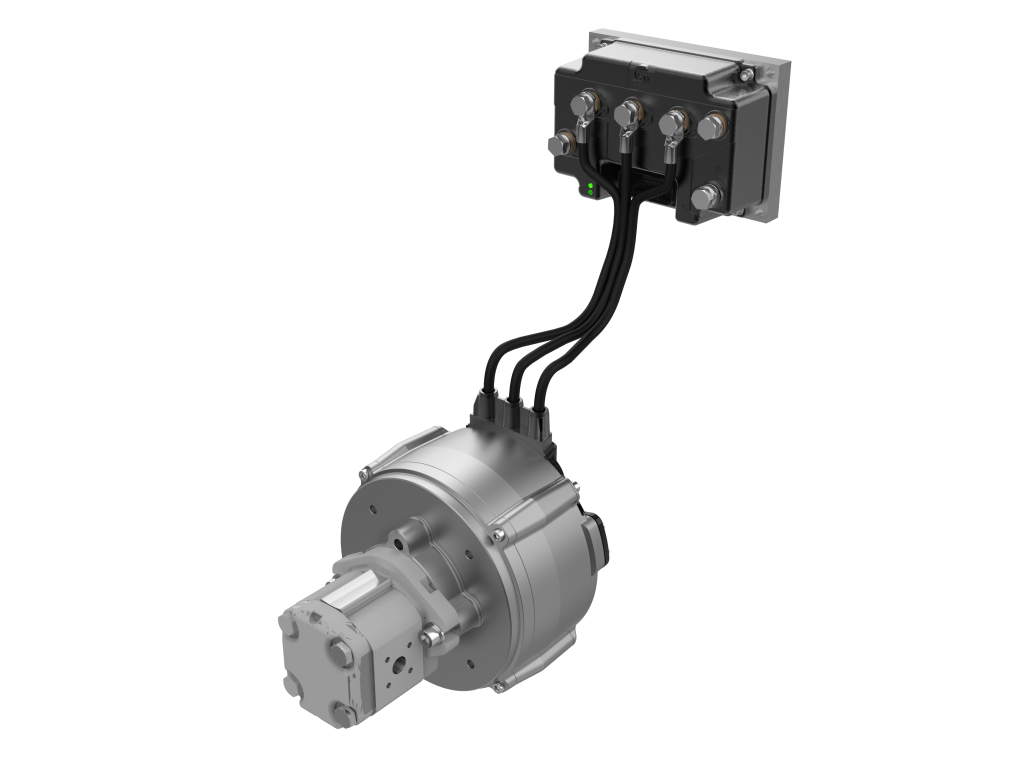

Electro Hydraulic Assisted Power Steer (EHPS) System (Gen II)

Motor/inverter/pump system

Max pressure: 180 Bar

Current: 182 A

Energy savings: 30-50%

Provides oil flow for assist steering applications by: 16 I/min @ 0…150bar, 14 l/min @ 180 bar (peak). Powered by 24Vdc (48Vdc on request) battery (Board net). Power is independent of engine speed.

Need more information?

REQUEST INFORMATION"With their superior efficiency, performance, competitive price and maintenance-free lifecycle, Dana TM4 e-powertrains are enabling our customers to get a faster ROI."

Burak Onur, Technology Manager at TEMSA Global

High-voltage systems features

- High-voltage, reluctance-assisted permanent magnet motors with 3-phase, 6-phase or 9-phase matching inverters

- High torque and power density

- Low electro-magnetic audible noise

- Low-cogging and ripple torque for better NVH

- Four-quadrant operation

- Double-ended shaft option

- Thermal protection

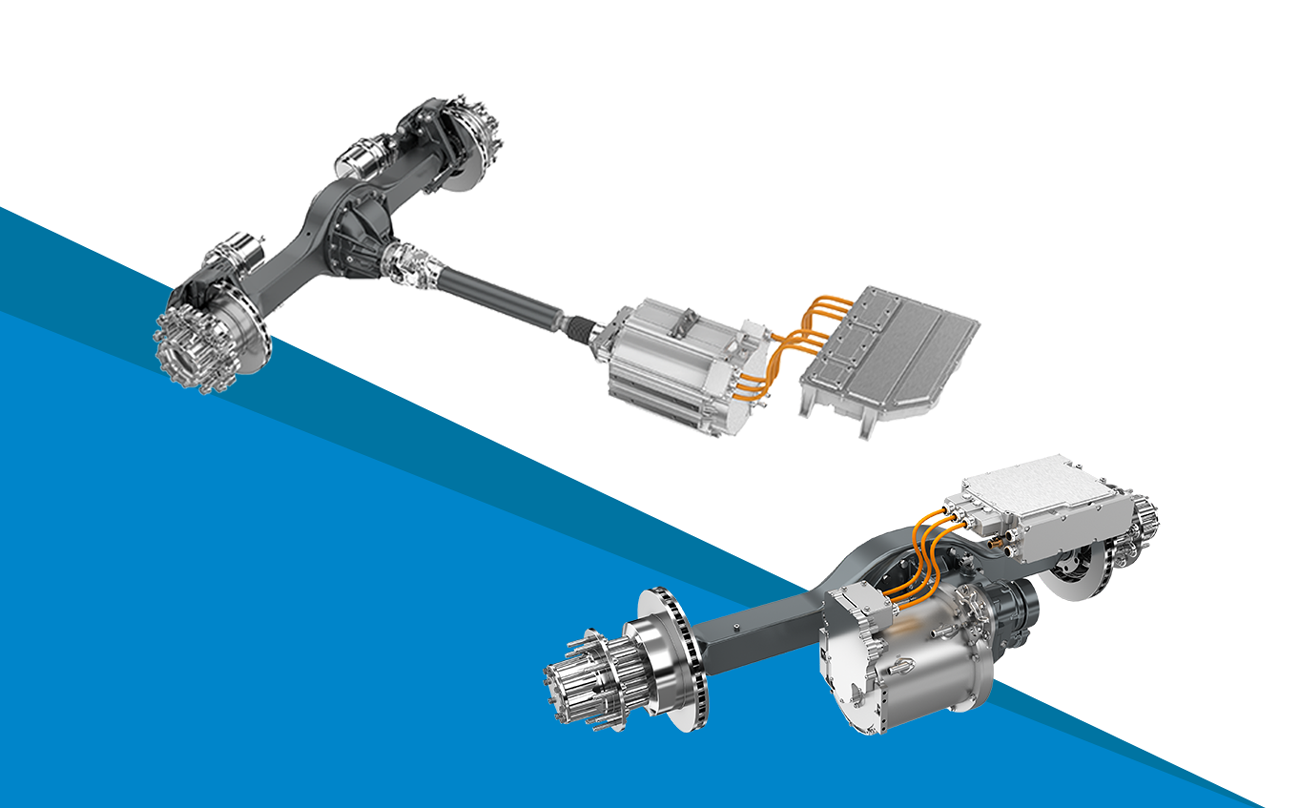

Integration into e-Axles, e-Drive Systems and e-Hubs

Dana TM4’s motors are available in various configurations. They can be purchased individually or integrated seamlessly with Dana’s e-Axles, gearboxes, and hubs.